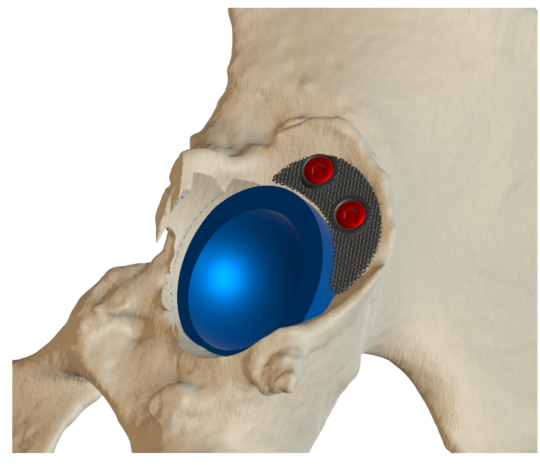

Acetabular cups and augments

Implants for pelvic and acetabular reconstruction with porous inserts at the bone contact points for better osseointegration. The implant is adapted for cement fixation of the friction pair.

The implant fasteners are calculated in advance during the preoperative planning stage. This makes it possible to plan the introduction of screws in the area of the highest bone density, provide access for installation, and adapt the shape of the fasteners in accordance with the defect.

- Surgery goest faster

- Less risk of infection

- Anatomical reconstruction of the defect

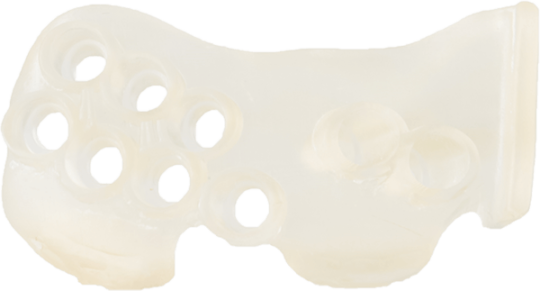

Corrective osteotomy

A set of surgical guides and fixation plates for various bone corrections.

The guides are made of high-strength biopolymers with the possibility of inserting metal grooves for the sawblade. The slots can be adapted to any type of saw.

The guides are designed taking into account the need for corrections in several planes.

Custom titanium products are fixed on prepared screw holes to minimize error.

The products have an anatomical shape, which ensures a better fit to the bone.

- Reduced operation time

- Anatomical shape for precise fit to bone

- Maximum precision during the surgery

- Possibility of using surgical guides with standard products

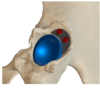

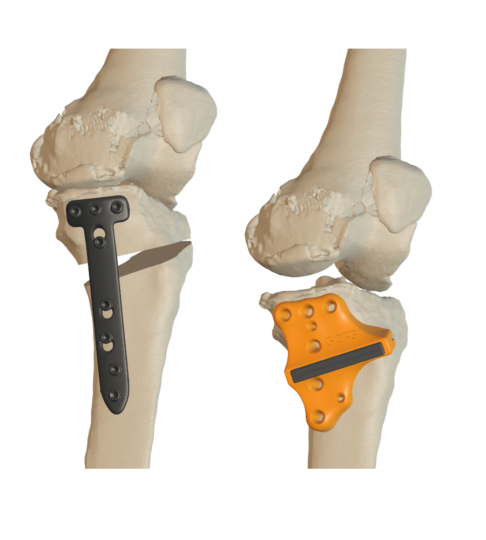

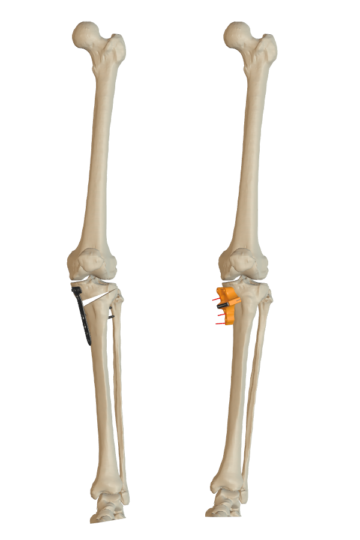

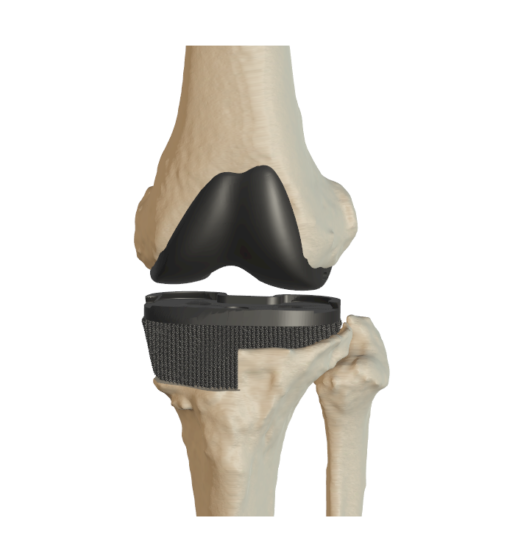

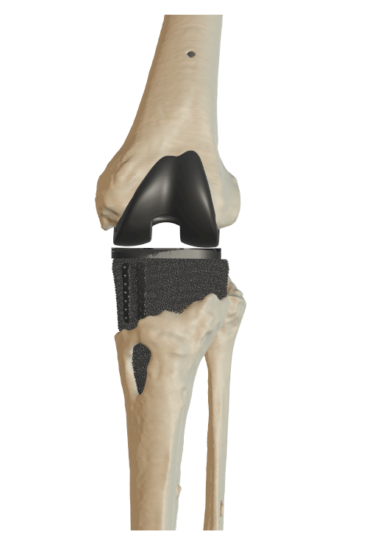

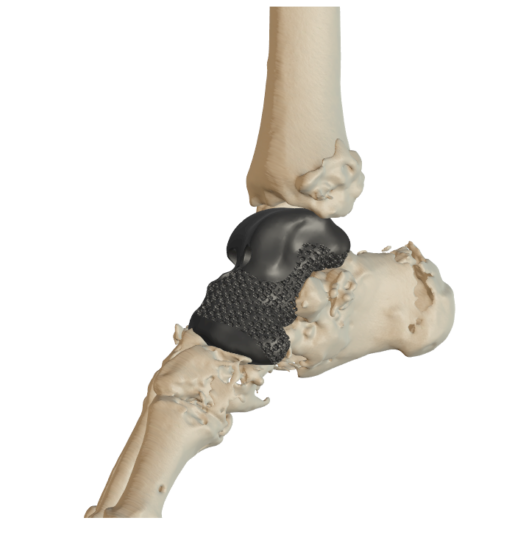

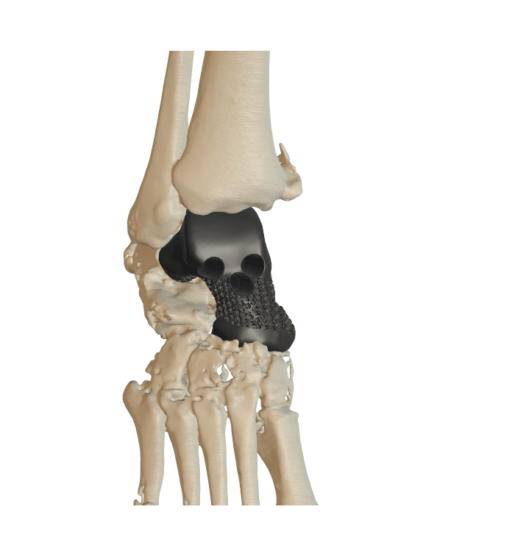

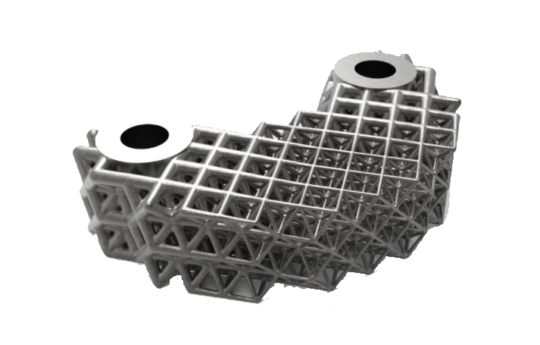

Augments (cones) for TKA

Implants for the restoration of bone defects in long bones containing porous titanium inserts that provide osseointegration.

Fully adaptable to all types of osteosynthesis, with the possibility of additional fixation on the implant itself.

- The operation is faster

- Less risk of infection

- Anatomical reconstruction of the defect

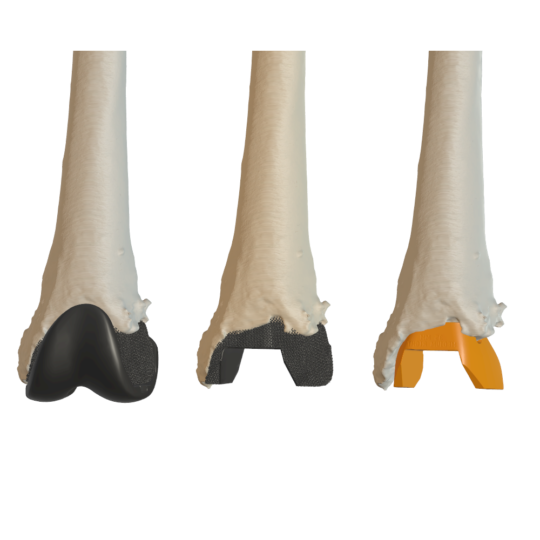

Replacement of the articular surface

Implants for the restoration of bone defects in articular surfaces.

The anatomical shape ensures a perfict fit of the implant to the bone.

Porous inclusions serve for osseointegration, and the polished surface allows you to restore smooth sliding in the joint. In this area, our company can provide a choice in the materials used.

Products can be made from medical grade titanium, high molecular weight polyethylene or medical PEEK

- The operation is faster

- Less risk of infection

- Anatomical reconstruction of the defect

Materials

Ti6Al4V ELI

The best material for the creation of implants and other medical devices is currently considered to be titanium and its alloys, which have a full range of properties that meet the requirements of medicine: high corrosion resistance, sufficient mechanical and cyclic strength, and wear resistance.

Sterilization of products from titanium alloys by boiling, autoclaving, formalin vapor, burning, immersion in alcohol does not damage the metal surface.

Due to the biological inertness of titanium structures to the human body, during implantation, they are not rejected and do not provoke allergic reactions, quickly being covered with musculoskeletal tissues, the structure of which remains constant throughout subsequent life.

It can be used both in solid models and in the form of a titanium mesh, or a porous cellular structure for better osseointegration.

Photopolymer Resin

Biocompatible material, ISO 13485 compliant and designed for healthcare professionals worldwide. Such medical materials can be used for applications that require contact with the patient’s skin, mucosa and blood.

Used for the production of medical guides, fixation templates and sterilizable anatomical models

UHMWPE

UHMWPE has very low water absorption for organic polymer compounds, therefore the properties of UHMWPE do not change when exposed to water. The main properties of UHMWPE, which determine its use, are very high wear resistance, low coefficient of friction and high fracture toughness.

It is used for the production of titanium / polyethylene friction pairs

PEEK

PEEK is a synthetic material that has many advantages in CMF reconstruction surgery: strength, stiffness, chemical inertness and durability. PEEK is used for cranioplasty and facial implants.

The material can be sterilized and reused (in case of failure due to infection) and can be easily modified during surgery using surgical instruments.

PEEK, as a polymer, has an extremely low thermal conductivity compared to titanium, which already has a low thermal conductivity compared to other metals.